Overview

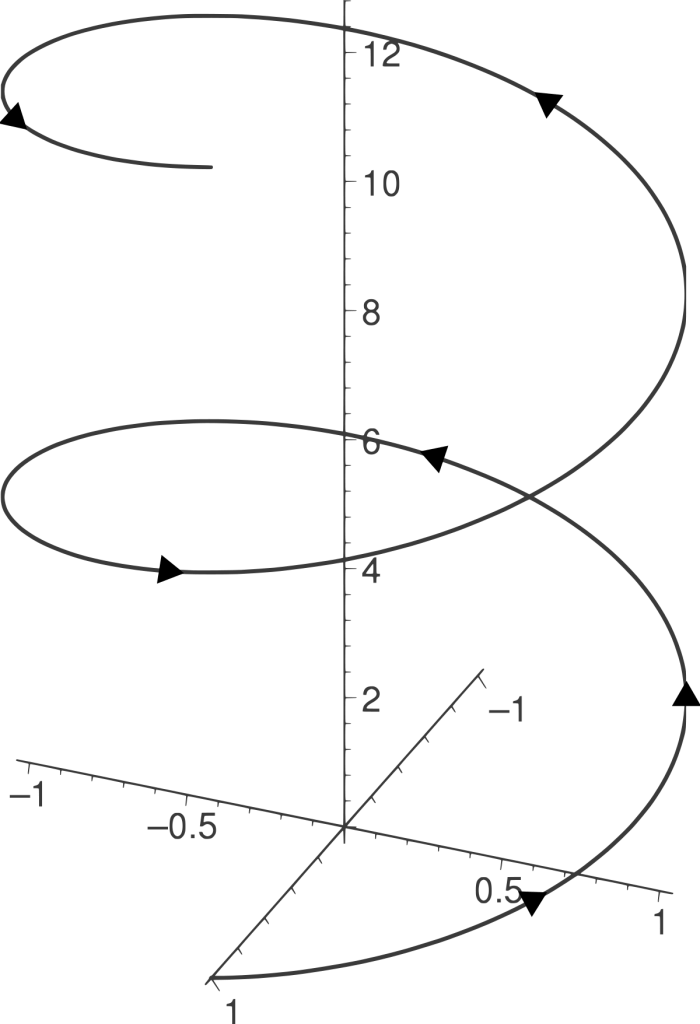

Conventional technologies which generate movement, or actuators, are rigid which limit applicability in robotics and medical devices. Soft actuators have many implications in soft robotics such as muscle like actuation for human interface devices. The introduction of a soft actuator will solve many problems such as weight, cost, maintenance, and rigidity introduced by conventional actuation technologies. A particular aim of this study is to observe which additive manufacturing technique can fulfill the need of high tolerance and resolution in order to print soft actuators as well as how additive manufacturing will affect the material properties of the helical dielectric elastomer actuator (HDEA). A silicone elastomer will be mixed with metallic

and carbon based additives to create the elastomer and electrode respectively and the new materials tested. With a material basis the limits of small and complex geometries will be evaluated at increasingly smaller scales to achieve the final helical geometry at an elastomer layer height of 100 μm. By conducting this research a knowledge of how to manufacture a soft actuator will establish a basis for the implementation of soft actuator technologies. The success of this research may allow for a muscle like soft actuation technology to further advances in soft robotics, prosthetics, and synthetic muscles.

Involvement

There were many students involved in smart material research of different kinds at Embry-Riddle Aeronautical University; My focus was in the ability to create the HDEA using additive manufacturing techniques. The additive manufacturing technique that would be used was inkjet printing due to its effectiveness considering the size requirements of the HDEA.

Having an additive manufacturing technique narrowed the process to creating the HDEA although further research was required into what combination of materials would create the closest to an ideal compound to be used for both the electrode and the elastomer. Different material combinations would give varying results in dielectric constant, strain, and response time to name a few. Further research would additionally conclude that mixing methods would affect the chemistry of the compound created which made it more difficult to predict material properties; this discovery made testing material properties all the more necessary.

All of these challenges pointed the team closer to testing methods and hands on application as opposed to simulation and theory. To fill this need I would move on to designing all research and experimental methods in order to manufacture the HDEA. Experimental methods included purchasing and handling of materials, mixing, and the inkjet printing of the material paired with a standard operating procedure to OSHA compliance for each step in the process.