Design Engineer

Shown are the most notable roles and responsibilities as my time as a Design Engineer.

Projects as a Design Engineer

My work centered on supporting aerospace manufacturing programs by translating engineering requirements into practical, repeatable production and inspection processes. I collaborated closely with manufacturing, quality, and engineering teams to ensure that parts could be produced and verified in accordance with design intent, industry standards, and internal quality systems. A significant portion of my responsibilities involved evaluating manufacturability risks, reviewing drawings and specifications, and identifying areas where tolerance, process flow, or inspection methodology could introduce variability or nonconformance.

I was involved in the development and refinement of tooling and inspection approaches, helping to ensure that production hardware could be consistently measured and validated against requirements. When discrepancies arose during manufacturing or inspection, I supported investigation efforts by analyzing measurement data, assessing potential root causes, and assisting in the development of corrective actions that balanced compliance, cost, and schedule. Through this role, I gained hands-on exposure to the realities of aerospace production environments and developed a strong appreciation for how design decisions directly impact manufacturability, quality outcomes, and program execution.

Investment Casting of Gas Turbine Vane

Investment castings use injection molded expendable patterns where several are usually joined together to form precision part features. The mold is formed by dipping the wax into a thick slurry until reaching sufficient thickness. Due to the nature of the single piece undercuts, apertures, and hollow may be easily produced¹.

Involvement

My role as a design engineer was to develop investment casting tooling by generating wax patterns for turbine vanes and flexible molds for ceramic cores while maintaining manufacturability. The intricate tooling design was developed using UG NX with the aid of complex surfacing techniques to capture the complex curvatures required. The design consistently adapted to the engineering needs of the product set by industry standards.

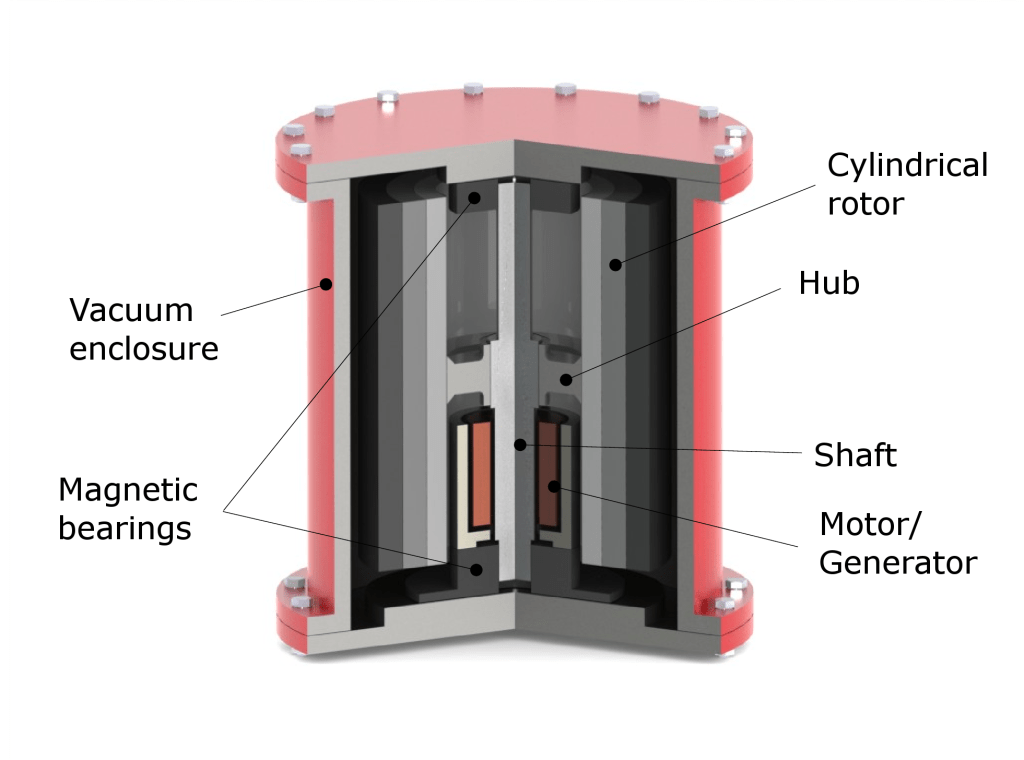

Flywheel Energy Storage System

A Flywheel Energy Storage System serves as a mechanical battery, using electrical energy to spin a high inertia flywheel converting the electrical energy into kinetic energy. The closed nature of the system will allow the flywheel to continue to spin until power is drawn from it, turning the energy from kinetic back into electrical energy.

Involvement

My role as an engineer is best expressed by the design optimization of the bearing and hydraulic systems required for the flywheel’s operation. A system of hydraulics and electronics are vital to peak performance of the system and balance of design requirements drive integration of certain design elements.

MRB Evaluation of Powerplant Parts

During my time I was responsible for providing Material Review Board (MRB) substantiation for aerospace components involved a disciplined engineering evaluation process intended to determine whether nonconforming hardware could be safely and compliantly dispositioned while preserving design intent, functional performance, and regulatory requirements. When discrepancies were identified through inspection or manufacturing feedback, I assessed the deviation in the context of the original design definition, applicable specifications, and downstream functional interfaces to establish whether the condition affected fit, form, function, strength, or durability.

Design analysis formed the foundation of this substantiation process. I reviewed the affected features relative to drawing requirements, datum schemes, and interface conditions to determine whether the nonconformance encroached on critical functional relationships. This frequently required evaluating how the discrepant feature interacted with mating hardware, seals, fasteners, or load paths, and whether sufficient margin existed within the original design intent. Where necessary, I examined historical design rationale, comparable configurations, or prior approvals to support equivalency arguments, ensuring that any deviation remained bounded by the assumptions used during original design development.

Tolerance stack-up analysis was a key component of MRB justification, particularly when dimensional nonconformances affected interfaces or assemblies. I evaluated worst-case and statistical stack conditions to determine whether accumulated variation could compromise assembly fit, alignment, or performance. This analysis often involved reassessing datum references, identifying which tolerances were truly functionally limiting, and demonstrating that the nonconforming condition did not drive the assembly beyond allowable limits when considered in the full tolerance chain. By grounding MRB decisions in quantitative stack-up analysis rather than nominal comparisons, I ensured that dispositions were technically defensible and repeatable.

For cases involving structural or load-bearing features, stress analysis supported MRB substantiation by demonstrating continued compliance with strength, fatigue, and cycle life requirements. I assessed how dimensional deviations, material conditions, or surface irregularities influenced stress concentrations, load distribution, or safety margins. Where appropriate, simplified analytical calculations or comparison to baseline stress cases were used to show that the nonconforming condition remained within allowable stress limits under expected operating loads. This approach ensured that MRB approvals were not based solely on dimensional acceptance but were explicitly tied to structural integrity and lifecycle considerations.

Process knowledge and automation played an important supporting role in MRB execution and documentation. I leveraged engineering automation tools, including scripted calculations and data processing workflows, to accelerate tolerance evaluations, normalize inspection data, and reduce manual error in recurring analyses. These process improvements improved consistency across MRB packages, shortened response time to manufacturing and quality teams, and enhanced traceability by ensuring that assumptions, inputs, and outputs were clearly documented and reproducible. By integrating design analysis, tolerance stack-ups, stress evaluation, and automated engineering workflows, I delivered MRB substantiation that balanced technical rigor, production efficiency, and regulatory accountability within an aerospace manufacturing environment.