Collegiate Career

Shown are the most notable experiences and opportunities that helped shape my career.

Formula SAE International

The Formula SAE competitions challenge teams of university undergraduate and graduate students to conceive, design, fabricate, develop and compete with small, formula style vehicles. The competition is an engineering education competition that requires performance demonstration of vehicles in a series of events, both off track and on track against the clock. Each competition gives teams the chance to demonstrate their creativity and engineering skills in comparison to teams from other universities around the world.

Teams are to assume that they work for an engineering firm that is designing, fabricating, testing and demonstrating a prototype vehicle. The vehicle should have high performance and be sufficiently durable to successfully complete all the event at the Formula SAE competitions. Each student team design will be judged and evaluated again other competing designs in a series of Static and Dynamic events to determine the vehicle that best meets the design goals and profitably built and marketed.

Formula SAE promotes careers and excellence in engineering as it encompasses all aspects of the automotive industry including research, design, manufacturing, testing, developing, marketing, management and finances¹.

Involvement

My contributions to the Formula SAE team began in a general role, assisting the team in design, fabrication, implementation, and test. These tasks were spread out among the Mechanical, Power train, Electrical, Aerodynamic, and Suspension sub teams. These tasks would define my role for my first semester until my election by the team to become the Electrical Team Lead responsible for the design and implementation of the next vehicle’s electrical system.

The responsibilities as the Electrical Team Lead were to execute the design, fabrication, test, and implementation of the electrical system which included vital electronics on the vehicle as well as data acquisition. The electrical team capitalized on previous systems by maintaining strengths and improving upon weaknesses. Beyond assembly, test, and integration of a robust system a modular sensor scheme was included to allow for performance analysis and optimization of the suspension, power train, and aerodynamic systems.

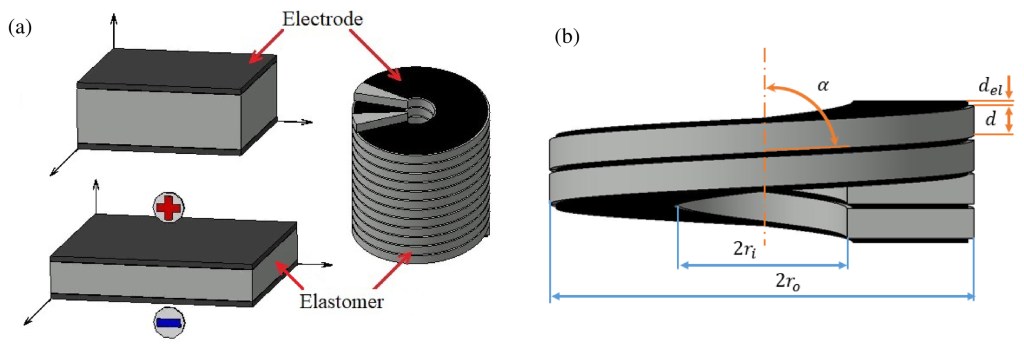

Additive Manufacturing of Helical Dielectric Elastomer (Soft) Actuator (HDEA)

Conventional technologies which generate movement, or actuators, are rigid which limit applicability in robotics and medical devices. Soft actuators have many implications in soft robotics such as muscle like actuation for human interface devices. The introduction of a soft actuator will solve many problems such as weight, cost, maintenance, and rigidity introduced by conventional actuation technologies. A particular aim of this study is to observe which additive manufacturing technique can fulfill the need of high tolerance and resolution in order to print soft actuators as well as how additive manufacturing will affect the material properties of the helical dielectric elastomer actuator (HDEA). A silicone elastomer will be mixed with metallic

and carbon based additives to create the elastomer and electrode respectively and the new materials tested. With a material basis the limits of small and complex geometries will be evaluated at increasingly smaller scales to achieve the final helical geometry at an elastomer layer height of 100 μm. By conducting this research a knowledge of how to manufacture a soft actuator will establish a basis for the implementation of soft actuator technologies. The success of this research may allow for a muscle like soft actuation technology to further advances in soft robotics, prosthetics, and synthetic muscles.

Involvement

There were many students involved in smart material research of different kinds at Embry-Riddle Aeronautical University; My focus was in the ability to create the HDEA using additive manufacturing techniques. The additive manufacturing technique that would be used was inkjet printing due to its effectiveness considering the size requirements of the HDEA.

Having an additive manufacturing technique narrowed the process to creating the HDEA although further research was required into what combination of materials would create the closest to an ideal compound to be used for both the electrode and the elastomer. Different material combinations would give varying results in dielectric constant, strain, and response time to name a few. Further research would additionally conclude that mixing methods would affect the chemistry of the compound created which made it more difficult to predict material properties; this discovery made testing material properties all the more necessary.

All of these challenges pointed the team closer to testing methods and hands on application as opposed to simulation and theory. To fill this need I would move on to designing all research and experimental methods in order to manufacture the HDEA. Experimental methods included purchasing and handling of materials, mixing, and the inkjet printing of the material paired with a standard operating procedure to OSHA compliance for each step in the process.

Student Exoskeleton Organization

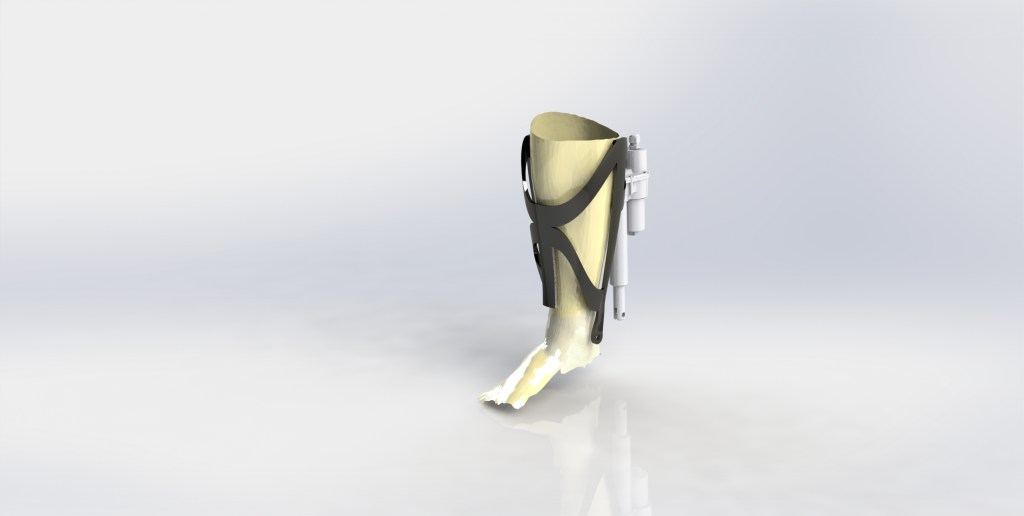

The Student Exoskeleton Organization (ExO) was started as a collaboration between the graduate students conducting research in soft actuation through smart materials and the biological studies laboratory at Embry-Riddle Aeronautical University. The purpose of the collaboration was to create a device that could later serve as a test platform for soft actuation technologies. The purpose of ExO is to create a series of medical assistive devices wherein each supplies half of the required work needed for full range of motion to the primary joint of that motion. A long term goal of the organization is to have many assistive devices applied at many vital joints of the human body to in aggregate form a ‘full’ exoskeleton.

The initial device designed by ExO is a knee assistive device that employs an electronic linear actuator to provide a force at some moment arm to simulate torque generated at the knee. The frame utilizes a patient specific 3D printed frame made from a carbon particulate nylon material and was designed and parameterized to the user in CAD. The goal of the geometry was to be as lightweight as possible while still being ergonomic to the user as well as sufficiently structural to handle all provided loads. The geometry was analyzed using FEA to simulate the stresses and deflections under highest possible load and under life cycle conditions.

The actuation of the device was dictated by a controller with integrated electromyography (EMG) which took signals from the brain which allows the device to predict movement from the user as they are moving. This minimizes the device instantiating movement instead of the user, or from having a delayed response. The purpose of this system is to use sensory input and control systems to create an assistive device that works as seamlessly as possible.

Involvement

Being part of the inception of ExO and one of the few graduate students to guide the project, I served as Vice President in my time with the organization. My time would be spent in both roles involving leadership of the team and administrative tasks as well as guiding sub teams within their particular tasks. Constructing teams based on their interests and strengths helped to keep teams engaged and productive.

I would assist teams in tasks such as geometric design, design for manufacturability, and control systems. As a researcher at the university for soft actuation many considerations had to be made for the existing device from the beginning to ensure a seamless integration of the soft actuator to any ExO device as a test platform and proof of concept.