Engineering Responsibilities

Shown are the roles and responsibilities I undertook during my tenure with my employer.

Reverse Engineering

I reverse engineered aerospace components in situations where original design data was incomplete, unavailable, or insufficient for production, requiring a disciplined approach grounded in engineering judgment and system-level understanding. Rather than relying solely on geometric replication, I analyzed functional interfaces, load paths, thermal environments, and assembly relationships to infer original design intent. This allowed me to distinguish between features that were critical to performance or safety and those that could be flexibly defined to improve manufacturability or inspection robustness.

My approach combined physical inspection, dimensional measurement, and analytical reasoning to reconstruct designs that achieved equivalent fit, form, and function. I evaluated how individual components interacted within the larger system, ensuring that reverse-engineered definitions preserved performance margins and operational compatibility. By grounding reverse engineering decisions in functional understanding rather than nominal geometry alone, I produced designs that were technically substantiable, production-ready, and aligned with regulatory expectations.

Project Management

I managed aerospace projects for part and/or assemblies across their full lifecycle, beginning with initial technical assessment and extending through design definition, manufacturing support, inspection readiness, and long-term sustainment. I developed and maintained project plans that integrated technical scope, schedule constraints, and resource availability, while ensuring that engineering decisions remained traceable and aligned with program objectives. Rather than treating project management as a parallel activity, I integrated it directly with engineering ownership, using technical milestones and risk assessments to guide prioritization and decision-making.

Throughout the lifecycle, I coordinated cross-functional stakeholders including design engineering, manufacturing, quality, FAA certifications and external customers to ensure alignment on requirements, deliverables, and timelines. I actively monitored technical risks such as tolerance sensitivity, manufacturability constraints, inspection feasibility, and compliance considerations, addressing these issues early to prevent downstream disruptions. By maintaining continuity between design intent and production execution, I ensured that parts and assemblies progressed through each phase in a controlled, predictable manner while meeting performance, quality, and delivery expectations.

Hard Gage Design & Implementation

I designed hard gaging solutions as an expansion of the engineering and quality verification process to ensure reliable and repeatable inspection of aerospace components. I developed gage concepts that were explicitly aligned with functional datums and critical design requirements, ensuring that inspection results directly reflected compliance with design intent. In doing so, I considered factors such as measurement repeatability, operator interaction, fixture stability, and long-term durability to support consistent results across production environments.

By integrating gage design early in the development process, I reduced ambiguity between engineering, manufacturing, and quality teams regarding how parts were to be verified. I ensured that gages supported efficient inspection workflows while maintaining sufficient accuracy to detect meaningful deviations. This approach strengthened the link between design definition and quality verification, minimized inspection variability, and reduced the likelihood of nonconforming parts escaping detection.

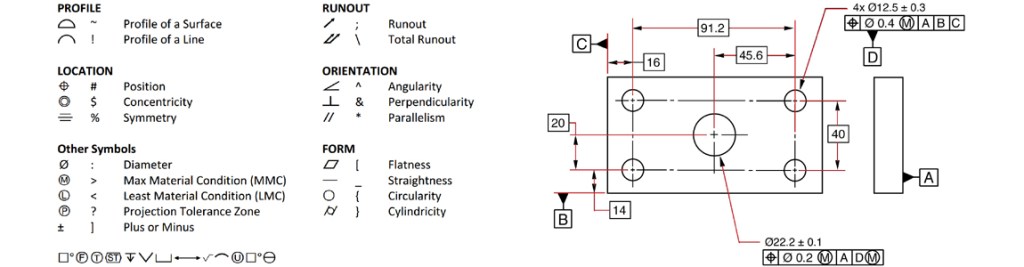

Application of GD&T principles

I applied GD&T principles to create design definitions that were both functionally robust and consistently interpretable across engineering, manufacturing, and inspection disciplines. I selected datum reference frames based on how parts were assembled, constrained, and loaded in service, ensuring that geometric controls reflected real-world functional relationships rather than arbitrary coordinate systems. Tolerances were applied deliberately, balancing functional requirements with manufacturability and inspection capability.

Through this disciplined use of GD&T, I avoided over-constraining designs that could drive unnecessary manufacturing risk or inspection complexity. I used tolerance stack-up analysis to validate that applied tolerances supported assembly-level requirements and preserved functional margins. By treating GD&T as a communication tool rather than a drafting exercise, I improved clarity, reduced interpretation errors, and supported repeatable production outcomes.

FAA Compliance

I ensured aerospace components conformed to relevant FAA compliance criteria by integrating regulatory considerations directly into engineering execution rather than treating compliance as a downstream activity. I applied an understanding of approval basis requirements, design substantiation expectations, and documentation standards to guide design decisions, inspection strategies, and nonconformance resolution. This ensured that technical solutions remained aligned with both performance objectives and regulatory obligations.

I maintained traceability between design intent, analysis, inspection results, and compliance documentation, supporting defensible approval packages and audit readiness. When addressing nonconforming conditions, I evaluated impacts through the lens of continued airworthiness, ensuring that dispositions preserved safety and regulatory compliance. By embedding FAA compliance awareness into day-to-day engineering work, I ensured that components met the standards required for approval, production, and sustained operational use.